Ultrasonic Basics

Process Definition

Ultrasonic plastics assembly is a process of joining or reforming thermoplastics using heat generated from high frequency mechanical vibrations. The electrical energy is converted into high frequency vibrations which create frictional heat at the joint area. The plastic in the joint area melts, creating a molecular bond between the plastic components. The high frequency sound vibrations cause an increase in temperature, causing the material to melt and either bond to the adjoining part or take the shape of the tool. The main difference between ultrasonic assembly and heat welding or forming is how the heat is introduced to the desired location, as ultrasonics transmits high frequency sound vibrations which travel through the material and cause heat to develop in the material itself.

How Ultrasonic Assembly Is Done?

Ultrasonic assembly converts high-frequency electrical energy into high-frequency mechanical motion by using a piezoelectric transducer and applied to the parts with force, causing the plastic to melt and form a molecular bond between the components. The process of ultrasonic assembly results in a homogeneous bond between the parts as the plastic cools.

Ultrasonic Welding

Ultrasonic welding is the most prevalent ultrasonic assembly application. In ultrasonic welding, the high frequency vibrating energy from a horn is applied to a work piece along with pressure, which causes the joint area between two parts to heat up due to frictional heat. The plastic material melts, and the parts are bonded together when the vibrations stop, and the plastic solidifies.

The process of ultrasonic welding is used to join two thermoplastic parts together by applying a controlled pressure to the parts and vibrating a titanium or plated aluminum horn vertically to generate frictional heat at the joint interface. The plastic is melted and then allowed to cool, and the clamping force is maintained during the hold time to improve the joint strength and hermeticity. Once the melted plastic has solidified, the clamping force is removed, and the two parts are joined as one.

Advantages of Ultrasonic Assembly

Ultrasonic assembly has numerous benefits such as:

- Fast, clean, efficient, and repeatable process

- Creates strong and integral bonds

- Consumes minimal energy

- Does not require solvents, adhesives, mechanical fasteners, or external heat

- Adaptable and versatile

- Ability to change tooling quickly

- Applicable to difficult materials

- Low-cost investment in ultrasonic equipment

- Reliability, long life, and consistent performance

Ultrasonic assembly is widely used across various industries including automotive, medical, electrical and electronic, communications, appliances, consumer products, toys, and textile and packaging. It can significantly increase production and reduce assembly costs.

System Components and Functions

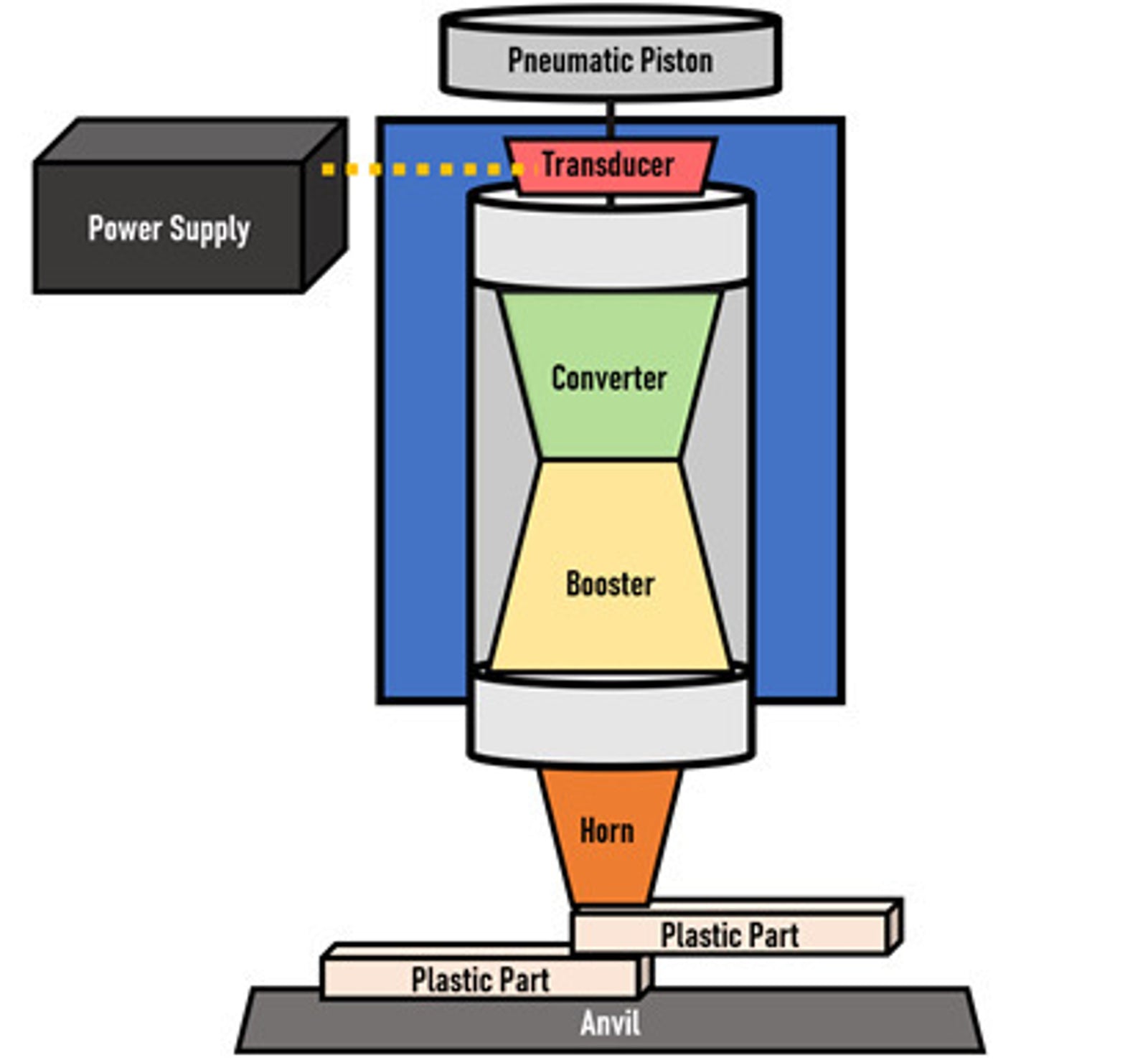

The four major components of an ultrasonic assembly system are:

- Generator (power supply)

- Transducer (converter)

- Booster

- Horn (acoustic tool)

The generator converts standard electrical power into electrical energy at the required frequency for the system (most commonly 15, 20, 30, or 40 kHz). The electrical energy is then sent to the transducer, which changes it into mechanical vibrations. A press and fixture are also required to complete the ultrasonic assembly system, but are not considered major components.

The booster is used to increase or decrease the amplitude of the vibrations to match the required application. The amount of increase or decrease is expressed as the gain, which is the ratio of the output amplitude to the input amplitude. The vibrations are then transmitted to a horn of the appropriate size and shape to deliver the vibrational energy to the workpiece. The horn may further increase the amplitude of the vibrations.

Techniques for Applying the Energy to the Work

The type of ultrasonic plastics assembly system used depends on the application, with options including:

- Hand-held convert-a-probe systems

- Press systems for more critical applications

- Rotary index parts handling systems for high production speeds

- Ultrasonic units with stack assemblies for very high-speed assembly

- Thrusters for custom installations where a press system may be too large

Each type offers different levels of control, repeatability, and ease of use for different production requirements.

Plastic Materials

Polymers are chemical compounds formed by combining two or more elements into a large molecule. There are two types of polymers:

- Thermosets: Not suitable for ultrasonic assembly because they are hard and brittle

- Thermoplastics: Ideal because they can be softened upon heating

Thermoplastics are classified as either amorphous or semi-crystalline, with the molecular structure determining the physical properties and melting and welding characteristics. Amorphous thermoplastics have a gradual softening process, while semi-crystalline materials have a sharp melting point. Semi-crystalline materials are more difficult to weld than amorphous materials because of their high energy requirement for melting and their ability to absorb vibrational energy.

Compatibility of Materials

When bonding two thermoplastic parts, it is important that the materials have compatible chemical properties. If the materials are not chemically compatible, even if they melt together, there will be no molecular bond. For example, polyethylene and polypropylene cannot be welded together. Similarly, only similar amorphous polymers have a good chance of welding to each other, while semi-crystalline materials can only be welded to themselves. Other factors such as hygroscopicity, mold release agents, and fillers can also affect the weldability of the parts.

Factors Affecting Weldability

Hygroscopicity

It is the tendency of a material to absorb moisture, affects the weldability of thermoplastic parts. Materials like polyamide, polycarbonate, polycarbonate/polyester alloy, and polysulfone are hygroscopic and therefore, if moist parts are welded, the water trapped within the material will boil off when the temperature reaches the boiling point, creating a foamy condition at the joint interface which makes it difficult to achieve a hermetic seal and compromises the strength of the bond. To avoid these issues, hygroscopic parts should be welded immediately after molding or stored in polyethylene bags with a desiccant to protect against moisture.

Mold Release Agents

The use of mold release agents on molded parts can negatively affect weldability as it reduces surface friction between the parts and the chemical contamination of the resin can inhibit the formation of a bond. The best choice for mold release agents are paintable/printable grades as they interfere least with ultrasonic assembly and often require no pre-assembly cleaning. Zinc stearate, aluminum stearate, fluorocarbons, and silicones should be avoided if possible as they are detrimental to ultrasonic assembly.

Lubricants

The use of lubricants such as waxes, zinc stearate, stearic acid, aluminium stearate, and fatty esters can negatively impact the ultrasonic bonding process. These lubricants improve the flow of the resin, but since they cannot be removed and reduce the friction at the bonding interfaces, they can defeat the entire ultrasonic process.

Plasticizers

Plasticizers increase the flexibility and softness of a material but can weaken the bond or joint over time due to migration. FDA-approved plasticizers are preferred but experimentation is advised before production.

Fillers

Fillers such as glass fiber, talc, carbon fiber, and calcium carbonate are added to resins to change their physical properties. Common mineral fillers can enhance the weldability of thermoplastics by improving the transmission of vibrational energy. However, a direct relationship between filler addition and weldability exists only within a specific range. Excessive filler content can result in agglomeration at the joint, making it difficult to achieve a consistent weld, and can also cause excessive wear on tooling and require more powerful ultrasonic equipment.

Flame Retardants

Flame retardants are added to plastics to change their flammability properties and prevent combustion. However, these retardants can weaken the strength of the final joint in thermoplastic welding and require the use of high-powered equipment operating at higher amplitudes to achieve sufficient strength.

Regrind

Regrind refers to recycled or reprocessed plastic material that is added to the original resin. Ultrasonic assembly allows the use of regrind without introducing any foreign substance. However, to achieve the best results, it is recommended to keep the regrind percentage low and ensure that the plastic has not been degraded or contaminated.

Colorants

The addition of colorants or pigments to plastics does not significantly affect the weldability of the material, except when the proportion of colorant to resin is excessively high. White and black parts may require more pigments, and different colours of the same part may require different setup parameters. It is advisable to experiment with the pigments before full production.

Resin Grade

The grade of the resin used in an application can significantly impact its weldability. Different grades of the same material can have varying melt temperatures, leading to poor welds or compatibility issues. It is recommended to use materials of the same grade for best results in ultrasonic assembly.

Joint and Part Design

Basic Requirements

The design of the mating pieces in assembly is crucial to achieve optimal results. Different joint designs exist, each with its advantages, and the choice of a particular design depends on factors such as the type of plastic, part geometry, and weld requirements. There are three essential requirements for joint design:

- A uniform contact area

- A small initial contact area

- A means of alignment

A uniform contact area ensures that the mating surfaces are in full contact around the joint, and the joint should be in one plane if possible. A small initial contact area minimizes the energy and time needed to start and complete the meltdown between the mating parts. A means of alignment prevents misalignment during the welding operation and can be achieved through molded alignment pins, sockets, channels, and tongues. It is best not to use the horn and/or fixture for alignment.

The Energy Director

The energy director is a triangular bead molded into the joint interface that provides a specific volume of material to be melted, resulting in good bond strength without excessive flash. This joint design is recommended for amorphous polymers. The energy director concentrates ultrasonic energy at the apex, causing a rapid buildup of heat and melting of the material which forms a molecular bond with the mating surface.

The energy director meets two of the three basic requirements for a joint design, providing a uniform and small initial contact area. A means of alignment and flash control must be incorporated into the part design. The common joint design with an energy director is the butt joint, with the width of the base being 20-25% of the wall thickness. If the wall is too thick, two smaller energy directors should be used.

The Step Joint

The step joint design is a variation of the energy director joint design, which meets two of the basic requirements of joint design: uniform contact area and small initial contact area. A step joint also provides alignment. The strength of the step joint is less than that of the butt joint with an energy director, and the recommended minimum wall thickness is 0.080" to 0.090".

The step joint is used when the cosmetic appearance of the assembly is important, as it eliminates flash on the exterior and produces a strong joint. The height and width of the tongue in the step joint should each be one-third of the wall thickness, and the width of the groove should be slightly greater to ensure no interference. The depth of the groove should be slightly greater than the height of the tongue to create a slight gap between the finished parts for cosmetic purposes.

The Tongue-and-Groove Joint

The tongue-and-groove joint is another type of energy director joint. It meets the three requirements of joint design: a uniform contact area, a small initial contact area, and a means of alignment, and also prevents flash on both sides of the interface. This joint is ideal for applications where self-location and flash prevention are important and for low pressure hermetic seals. However, it has a lower potential for weld strength compared to other joint designs, and a minimum wall thickness of 0.120" to 0.125" is recommended.

The Shear Joint

The shear joint is used when a strong hermetic seal is needed and is best suited for semi-crystalline resins. A certain amount of interference is designed into the part for welding to be accomplished. The smearing action of the two melted surfaces at the weld interface eliminates leaks, voids, and exposure to air, resulting in a strong structural weld. A fixture is necessary to provide rigid sidewall support and prevent part deflection during welding.

Part Design

Near Field vs. Far Field Welding

The location of the joint in relation to the area of horn contact is critical in ultrasonic welding applications. Near field welding, where the distance between the horn and joint interface is 1/4" (6mm) or less, is preferred over far field welding. Far field welding, which requires higher amplitudes, longer weld times, and higher air pressures, is generally only advised for amorphous resins that transmit energy better than semi-crystalline resins.

Parallel Contact

The optimum weld is achieved when the joint interface is on a single plane parallel to the horn contact surface. This allows the ultrasonic energy to travel the same distance through the plastic part to reach the joint. Additionally, the surface that the horn contacts should also be on a single plane parallel to the joint.

Other Part Design Considerations

Sharp Corners

The sharp corners in plastic parts can lead to high stress and increase the likelihood of fracturing or melting under ultrasonic vibratory energy. To prevent this, it is recommended to have a generous radius on all corners and edges to reduce stress.

Holes or Voids

Holes, voids, angles, and bends hinder the transmission of ultrasonic energy, which may result in low or no welding in these areas. To optimize welding, sharp angles, bends, and holes should be eliminated where possible.

Appendages

Protrusions on plastic parts can cause stress and degating (falling off) when subjected to vibratory energy. To minimize this, a generous radius can be added at the junction, a light force can be applied to dampen the flexure, the appendages can be made thicker, or 40 kHz equipment can be used if possible.

Diaphragmming

Thin flat circular parts can bend and flex under ultrasonic energy, leading to melting or burning due to the heat generated. To prevent this "diaphragmming," making the affected areas thicker is recommended.

Other Assembly Techniques

Staking

Staking is a process of mechanically locking two parts together by melting and reforming a stud. This process is used when welding is not possible due to dissimilar materials or when mechanical retention is enough. Staking has advantages such as short cycle time, tight assemblies, good process control and repeatability, and eliminates the need for consumables like screws or adhesives.

The Standard Rosette Profile StakeThe standard rosette profile stake is a basic staking design that can satisfy most requirements and is used for staking flat-headed studs with a diameter of 1/16 inch or larger. It creates a head with twice the diameter of the original stud and is recommended for non-abrasive rigid and non-rigid thermoplastics.

The Dome Stake

The dome stake is used for smaller studs or when horn alignment is a challenge and is also recommended for glass-filled resins to prevent horn wear. The stud end should be pointed to ensure a small initial contact area, and horn and stud alignment is less critical than with the standard rosette profile stake.

The Hollow Stake

The hollow stake is used for studs larger than 5/32 inches in diameter and helps prevent surface sinks and internal voids during molding. It reduces the ultrasonic cycle time by melting and reforming less material and produces a strong, large head. In case of repairs, the formed head can be removed and reassembled by inserting a self-tapping screw in the hollow stud.

The Knurled Stake

The knurled stake is a simple and fast staking method that can be used with all thermoplastics. It allows for multiple stakes to be made without worrying about precise alignment or stud diameter and is not concerned with appearance.

The Flush Stake

The flush stake is used when a raised stud head above the surface of the attached part is not allowed. It requires a tapered stud design and the hole in the part to be attached is countersunk to allow the melted stud to fill that area and secure the attached part in place.

Stud Welding

Ultrasonic stud welding is an alternative to staking and is used to join plastic parts of similar material at single or multiple points. It is useful in applications where other techniques are not feasible due to material, size, or complexity. In this process, a stud is driven into a hole and welding occurs along its circumference to form a shear joint.

Insertion

Ultrasonic insertion is a process of embedding a metal component in a thermoplastic part. A hole is pre-molded into the thermoplastic part that is slightly smaller than the O.D. of the insert. The ultrasonic energy applied to the insert generates frictional heat which melts the plastic, allowing the insert to be driven into place. The process is completed in less than one second and the insert is surrounded by the melted plastic.

Swaging and Forming

Swaging is a process of assembling two materials by melting and reforming a ridge of plastic to capture another component, typically a dissimilar material like glass. It is a fast and efficient method of assembly without creating a molecular bond. Swaging requires special tooling and consideration of the material properties involved. The shape of the swage is determined by the horn face, which controls how the plastic melts and flows. The swage can be continuous or segmented.

Spot Welding

Ultrasonic spot welding is a method of joining two like thermoplastic components at specific points with no pre-formed hole or energy director. This process produces a strong bond and can be used on large parts, sheets of thermoplastic, and parts with complex shapes or hard-to-reach surfaces. The basic guidelines for spot welding include using a rigid support, medium to high amplitude, and low pressure.

Degating

Ultrasonic degating is a process used in separating injection molded parts from their runner systems. It involves applying ultrasonic energy to the runner in an out-of-phase manner, causing the parts to melt off at the gate. It is best used with rigid thermoplastics such as ABS, styrene, or acrylics and has advantages such as quick operation, low stress on parts, and a clean break at the part surface.

Scan Welding

Scan welding is a high-speed ultrasonic welding process for flat thermoplastic parts that are conveyed beneath a stationary or rotary horn and anvil. It can be used for both large and small parts with at least one flat surface for horn contact, and is suitable for rigid thermoplastics and some fabric or film applications. The joint design should be self-locating, such as tongue and groove, step, or pin and socket.

Bonding and Slitting

Ultrasonic Bonding

Ultrasonic bonding is a technique used in the textile, apparel, and nonwoven industries to assemble two or more layers of nonwoven materials by passing them between a vibrating horn and a rotary drum. The high frequency mechanical motion and compressive force between the horn and drum create frictional heat, bonding the materials together at the horn/material contact points.

Ultrasonic Slitting

Ultrasonic slitting is a process used to seal the edges of a thermoplastic material by passing it between a vibrating horn and a rotary cutting wheel (anvil). This process also seals the edges of woven fabrics and can be used to slit and melt together two or more layers of woven and/or nonwoven materials.

Major Component Design

Generators

Ultrasonic generators are electrical devices that take standard AC electrical power and transform it into electrical energy at a specific frequency. The frequency of the output can range from 15 kHz to 40 kHz and the output power levels can go up to 4,800 watts. The generators use a power amplifier that switches transistors on and off at a rate of 20,000 or 40,000 cycles per second.

Microprocessor Control

The digital timer in ultrasonic assembly systems acts as the "brain" of the system, controlling the up and down movement of the press/thruster slide and turning on and off the ultrasonic energy produced by the generator. It stores lists of instructions, or modes that can be altered to select variations in the weld cycle by adjusting weld times, hold times, and system parameters.

Transducers

Transducers are used to convert electrical energy received from a generator into mechanical energy in the form of high frequency vertical vibrations. They use piezoelectricity, which generates electricity or electric polarity by compressing a crystalline substance. The heart of a transducer is the piezoelectric ceramic elements which expand and contract dimensionally when exposed to alternating electrical energy.

Boosters

Boosters serve two main purposes: providing a second mounting point for the stack assembly and amplifying or reducing the amplitude. There are two types of boosters: standard boosters with split mounting rings and patented resonant boosters with no "O" rings for solid fixed mounting. Boosters can be made of titanium or aluminium and come in different gain ratios to adjust the stack amplitude to the requirement of melting the plastic in each application.

Presses

The ultrasonic press is a machine that applies ultrasonic energy to the workpiece to create consistent and satisfactory welds. The effectiveness of the press depends on the stability and reliability of its structure, with steel components providing greater structural integrity than aluminum ones.

Slide Assembly Design

The design of the slide assembly in an ultrasonic press plays a crucial role in determining the efficiency and longevity of the machine. Some designs, such as those with bronze bushings, can experience wear and migration issues due to cold flow properties. Linear ball slides are a more durable and accurate option, with no clearance between the bushing and rod, minimizing operating friction.

Force

The ultrasonic press is typically operated using air pressure from an air cylinder, which is controlled by a gauge and regulator. Some ultrasonic welders offer an electronic option to set and monitor pressure levels using an ultrasonic process controller, load cell, force transducer, and electronic pressure regulator.

The Bottom/Mechanical Stop

A bottom/mechanical stop adjustment is typically provided on a press to prevent the horn from accidentally hitting an empty fixture or to repeatably weld parts to a finished height. However, variations in dimensional part tolerances can cause the amount of meltdown to vary, even if the stroke is stopped at the same height each time.

Integrated vs. Modular Press Systems

There are two types of press systems available: the integrated system and the modular system. The integrated system is a self-contained unit with the generator housed inside the press, while the modular system has the generator housed in a separate chassis connected to the press with cables.

Horns

The horn plays an important role in ultrasonic assembly as it helps to transmit the ultrasonic vibrational energy to the workpiece, allowing for the localization of the melt in the desired area. The design of the horn is crucial and must be customized based on the specific requirements of each application.

Gain

A horn in ultrasonic assembly may have a gain factor, meaning it can increase the amplitude of vibration received from the transducer-booster combination. The gain and nodal stress of a horn depend on its cross-sectional shape.

Horn Materials

Horns are used for various applications and are made of different materials like aluminium, titanium, or steel depending on their acoustical properties, fatigue strength, and surface hardness.

Slots

To reduce the internal stresses and ensure uniform amplitude on the horn face, slots are machined into horns beyond a 4.0" (101.6mm) diameter or a 3.5" (88.9mm) length.

Composite/Compound Horns

A composite horn, also known as a compound horn, is a combination of individual horns (horn tips) attached to a coupling horn to form a single, full-wavelength unit.

Contoured Horns

Contoured horns are a common type of horn design that is used to maximize the energy transfer to the part being welded. They are designed using computer 3-D design software and are shaped to surround the part to be welded.

Replaceable Tips

In some staking and spot welding applications, a replaceable tip made of titanium may be used for the horn. The tip threads into a one-half wavelength horn that is also made of titanium.

Tuning

A horn's operating frequency is determined by the length of the horn and can be calculated using the formula of wavelength. The operating frequency is usually either 20 kHz or 40 kHz and is displayed electronically on a horn analyser.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) software is used by ultrasonic tooling engineers to test horn designs before manufacturing. This helps optimize horn design and performance by identifying and analyzing stress points, minimizing amplitude irregularities, and optimizing the horn to operate with a 20 kHz ultrasonic signal.

Fixtures

A fixture is a crucial component in ultrasonic assembly applications that serves two purposes: alignment and support. It aligns the part under the horn to ensure repeatability and supports the joint area for efficient energy transmission.

Process Control

What Is Process Control?

Process Control is a continuous improvement method for product and process quality. It involves four steps: operating a process with a requirement, measuring a variable against the requirement during operation, comparing the result to the requirement, and taking corrective action if needed.

Open-Loop (Time-Priority) Welding Systems

Open-loop, time-priority welding is a method in ultrasonic plastics assembly where parts are welded for a predetermined time duration. The horn descends and the ultrasound is turned on for the preset time, but there is no process data provided about the work being done.

Closed-Loop (Energy-Priority) Welding Systems

Closed-loop, energy-priority welding is a method of ultrasonic plastics assembly that welds parts based on the amount of energy they absorb, instead of a pre-set time duration. The horn descends and touches the part, then the ultrasonics is turned on and remains on until the pre-set energy level is reached.

Microprocessor Control

With the advent of computer-controlled ultrasonic welding equipment, the process of welding plastic parts became more precise and efficient. The use of microprocessor technology allowed for the gathering and logging of process data for statistical process control analysis, more efficient automation and system integration, reduced setup time, and control and monitoring of process variables on a cycle-by-cycle basis.

Ultrasonic System Features – Pneumatic

Electronic Pressure Regulation

Electronic pressure regulation uses an electronic pressure regulator and a pressure transducer to provide precise control and monitoring of press air pressure during the welding process.

Load Cell (Force Transducer)

The ultrasonic welder uses a load cell or force transducer to measure the force applied during the welding process.

Remote Setup Switching

The ultrasonic welder has the capability to change welding setups remotely, through a signal from an external source such as a programmable logic controller.

Sequencing

Sequencing is a feature of the ultrasonic welder that allows it to change setups after a specified number of welding cycles or based on inputs from external sources, such as a programmable logic controller or sensor.

Weld by Distance

The ultrasonic welder process controller is capable of precise distance measurement with the use of a linear encoder. This enables the system to join plastic components with a specific weld depth through "weld by distance."

Dual Pressure

The Dual Pressure technique in the ultrasonic welder process controller allows for more flexibility in the welding process by offering the option to weld at one pressure and hold at a second pressure, or to weld at two different pressures and hold at the second pressure.

Ultrasonic System Features – Servo

Sensing Start Distance and Sensing Speed

The ultrasonic welder servo systems feature several pre-weld options that are critical for setup and form part of the triggering sequence. These options include Sensing Start Distance and Sensing Speed, which determine the speed at which the press system's horn moves towards the part to be welded.

Start Motion at Force Drop

The Start Motion after Force Drop feature in the ultrasonic welder servo system identifies a specific point in the welding cycle, marked by the detection of a programmed drop in force.

Weld Motion Type

This feature refers to the ability to customize the speed of the horn during the welding cycle. The servo ultrasonic welder has two options for speed distribution: Constant and Profile.

Hold

The hold feature is a post-weld operation that allows for compression of the molten polymer as it solidifies to prevent residual stress and voids in the bond area. The servo ultrasonic welder offers three hold sequences: Dynamic, Static, or a combination of both.

Teachable Top of Stroke Position

The servo ultrasonic welder is equipped with a feature that allows the welder's thruster to return to the top of stroke position after a welding cycle. The top of stroke position can be directly programmed or taught using dual opto-touch switches and a computer interface.

Position Teaching

In addition to the top of stroke position, other positions such as Sensing Start Distance and Mechanical Bottom Stop can also be taught during the welder's setup phase.

Setup Switching

A setup on the servo ultrasonic welder includes all the programmed parameters for a specific welding process and can be saved digitally in memory.

Duplicating Process on Multiple Machines (clones)

The servo ultrasonic welder allows for multiple machines (welders) to be programmed with the same welding process, but this presents a challenge for pneumatic systems due to the minor mechanical differences between each welder.

Ultrasonic Welding Servo System Benefits

Weld and Hold Collapse Distances Control

The servo ultrasonic welder system offers more precise control of weld and hold collapse distances than pneumatic systems, thanks to its direct control method. In pneumatic systems, the collapse distance is controlled indirectly by releasing pressure from the air cylinder, but this can result in variations due to factors such as the limited rate of compressed air release.

Rapid Speed Change

In ultrasonic welding, profiling the speed during the weld can improve the weld quality by matching the natural rate of melt of the material. The servo ultrasonic welder, with its capability of changing speed quickly and its 50 in/s2 acceleration rate, enables meaningful weld profiling which allows for independent programming of up to 10 different segments of the weld, and dynamically senses when melt is initiated.

Versatility

The servo ultrasonic welder system is versatile and has advantages over pneumatic systems in handling difficult welding applications. One example is the sealing and cutting of thin film media, where precise distance control is required for quality welds.

Hold Phase

The servo ultrasonic welder offers improved control during the hold phase of welding, which has two stages: dynamic and static. In the dynamic stage, the parts are collapsed further after the ultrasound is turned off. In the static stage, the servo maintains its final position to allow the solidification process to finish.

Ease of Calibration

The servo ultrasonic welder is easier to calibrate compared to pneumatic systems as it eliminates pneumatic components. This means that the setup and maintenance of the system is simpler and more straightforward, leading to a more efficient and cost-effective operation.

Welder cloning is Easier

With servo, ultrasonic machines (welders) can be programmed to have the same performance, making it easier to achieve repeatable results when welding a high volume of parts. This is because the digital process control eliminates the need to compensate for minor mechanical differences between welders, which can be a challenge with pneumatic systems.

Rejects Reduced

The use of servo ultrasonic welder system leads to a decrease in the number of rejects due to its high degree of process repeatability, resulting in improved yields and a higher value of assembled parts.

Smaller Maintenance Cost

The servo system eliminates the need for a compressed air system, leading to cost savings in terms of operating a compressor and lower maintenance costs. The servo actuator has a long lifespan of over 200 million cycles.

Fewer Accidental Changes

The servo ultrasonic welder is designed to maintain process repeatability and calibration by eliminating adjustable mechanical operator controls, thereby preventing accidental or unauthorized changes.

Conclusion

Ultrasonic welding is a versatile and efficient method for joining thermoplastic materials. It offers numerous advantages over traditional joining methods, including speed, cleanliness, and the ability to join dissimilar materials. The technology continues to evolve, with servo-driven systems offering enhanced control and repeatability compared to pneumatic systems. As the demand for precise and reliable joining methods in industries such as automotive, medical, and electronics continues to grow, ultrasonic welding is likely to play an increasingly important role in manufacturing processes.