VERTEX mini/MAX Series

Newest model with self-calibration, temp controls, presets, data export, and more.

VERTEX mini/MAX Series is backordered and will ship as soon as it is back in stock.

Contact us! Our Sales Engineers are here to guide you on plastics joining and help you select the right machine. Reach out for inventory levels, pricing, or to make a purchase.

VERTEX Series Heat Staking Machines

VERTEX MINI & VERTEX MAX side by side.

Key Features

- ✓ Self-Calibration Procedure, an industry first, for increased accuracy & compliance

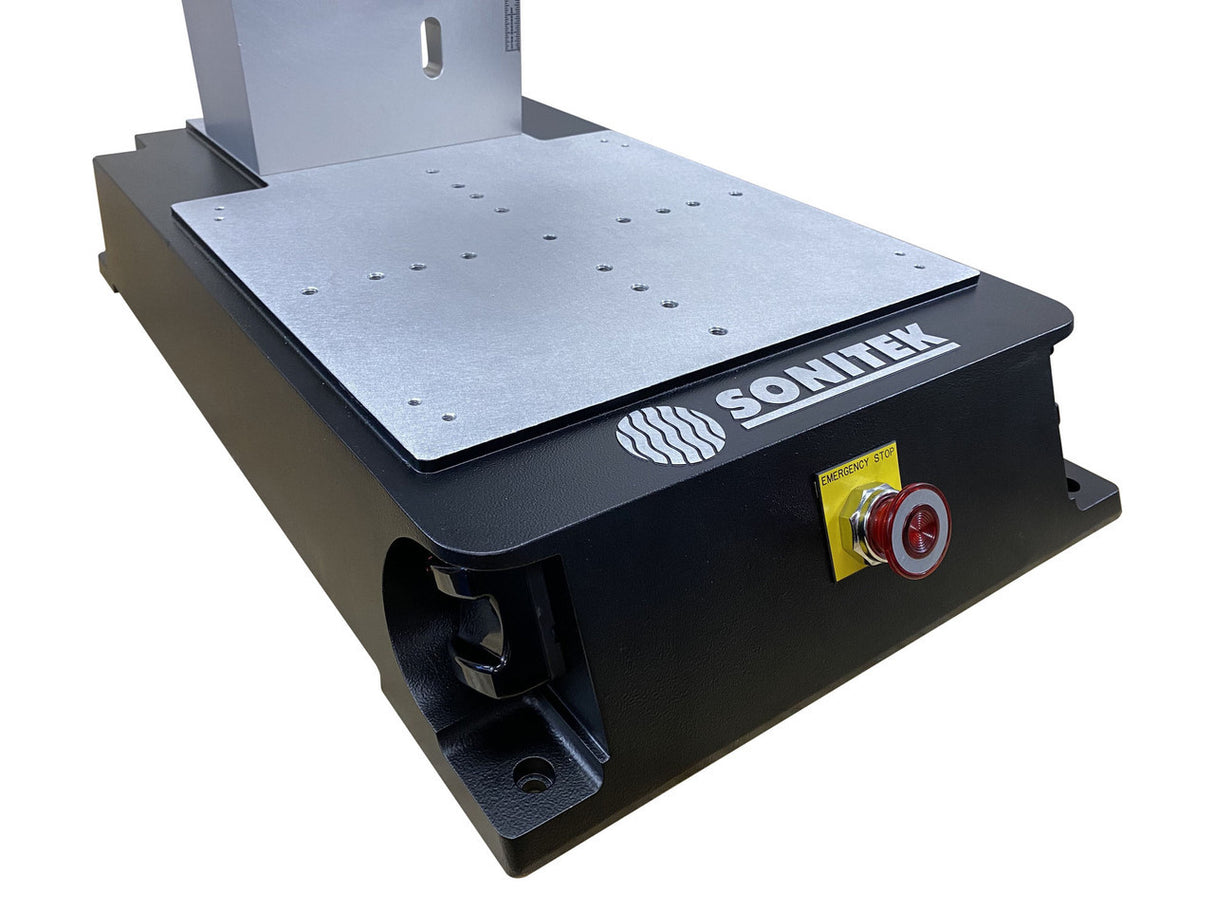

- ✓ Extra-large Blanchard ground cast aluminum working platform with bolt hole circle patterns for mounting lower jigs and fixtures

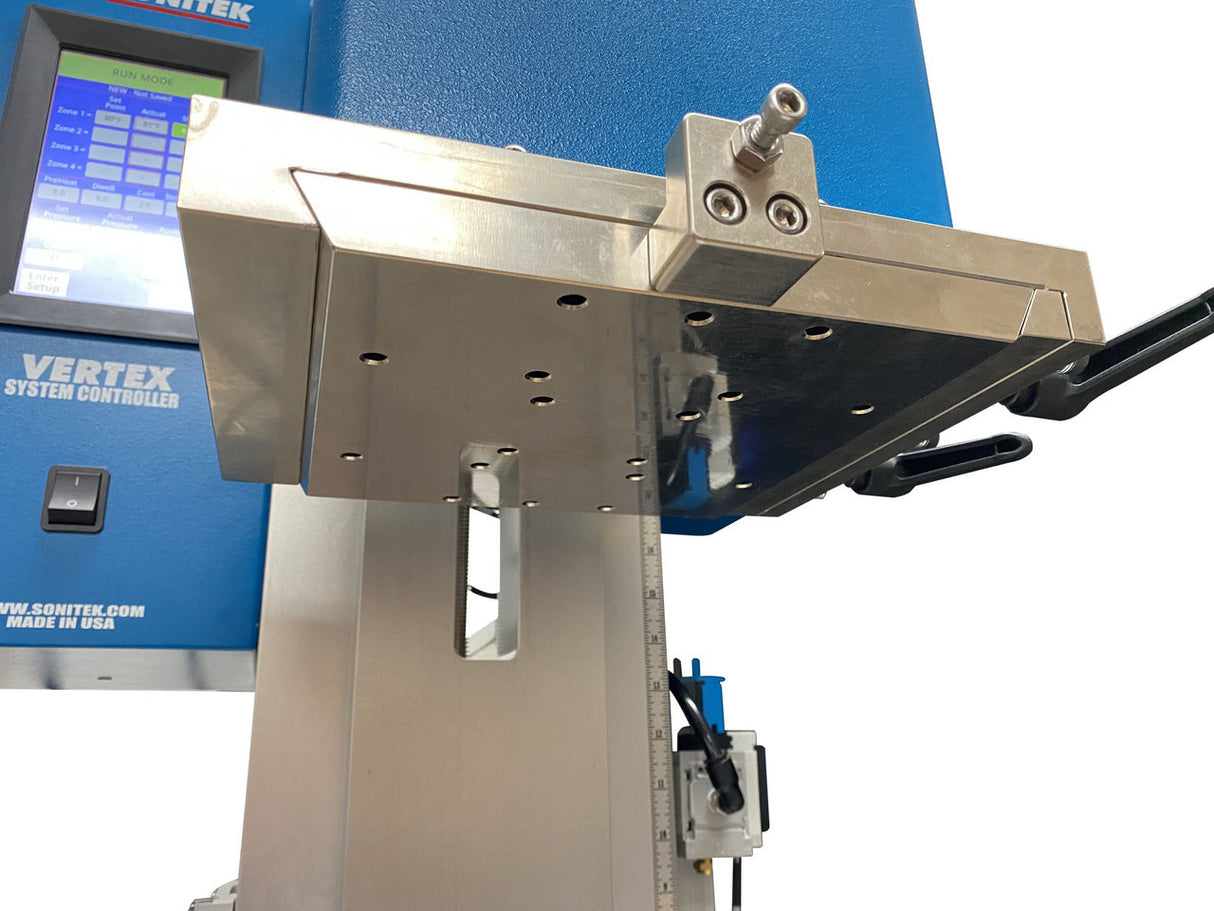

- ✓ Precise dovetail actuator support with new rigid column design for accurate and repeatable gross head adjustment, equipped with position indicator and hand crank for easy adjustment

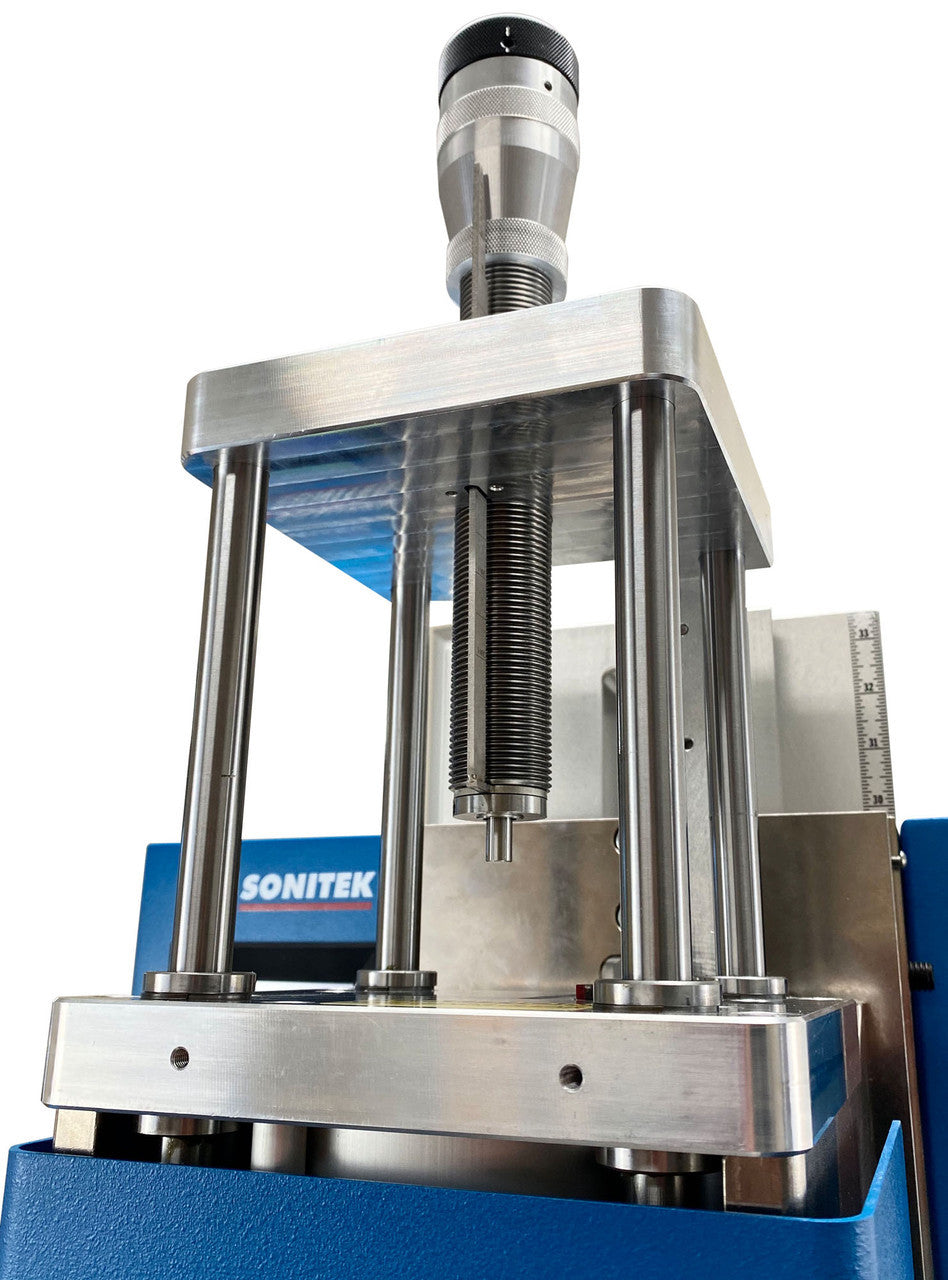

- ✓ 4-Post design precision guided non-rotating thruster/actuator with eight precision bearings and four ground and plated shafts for precise and repeatable process

- ✓ Available in two press sizes: VERTEX & VERTEX MAX. Comparison image (.JPG) & Comparison Dims. (.PDF)

- ✓ Available in 4 thruster/actuator sizes (force values are at @ 100 psi):

- Vertex MINI Press:

- V3 model = 300 lbs.

- V5 Model = 700 lbs.

- Vertex MAX Press:

- V10 Model = 1250 lbs.

- V20 Model = 1960 lbs.

- Vertex MINI Press:

- ✓ 5" (127mm) stroke with adjustable micro-positive stop with .001" increments

- ✓ Thermal Runaway alarms with automatic heater shut off

- ✓ Heater shut down with any loss of line pressure or E-stop function

- ✓ Head Speed Controls for pneumatic portion of head travel for UP and DOWN speed control

- ✓ Velocity and Distance Control unit model VCU for dual stage speed control and precision adjustment of stake depth. (VCU instruction video)

- ✓ JOG MODE! New Feature: jog head up and down for setups

- ✓ Line pressure regulator (FR) with digital gauge read out and filter with dump valve and lock-out/tag out

- ✓ Rigid tool mounting plate for mounting upper heated tooling

- ✓ Vertex Digital micro controller system with 5" (MINI press) or 7" (MAX press) COLOR touch screen HMI that controls ALL Process Parameters including timers, temperatures and multilevel alarms

- ✓ HMI Integrated auto-tuning temperature controls

- ✓ Dynamic zone and heater output assignments via HMI allows for easy configuration of multi-zone tooling change-overs

- ✓ Secondary Temperature monitoring of tooling mode (view without control)

- ✓ JOB PRESETS - Multi Preset storage to store, recall, and assign parameters

- ✓ Resettable & Lifetime cycle part counters

- ✓ Hybrid Automation capable with I/O output and control options and accessories panel for rotary tables and integration of automation components and peripheral devices

- ✓ Multi-level Password Protection to prevent unauthorized access to controls

- ✓ Sonitek 4-zone temperature controller (upgradeable to 8 zones on MAX press) features a touchscreen for setting temperature in °F or °C, easy auto-tuning, and quick-connect heater/thermocouple connections at the rear.

- ✓ THREE Year Limited Warranty

Heat Staking Processes

Insertion

Standard tips available for inserts up to 3/8" or M10

Staking

Custom platens available to stake several studs/tabs simultaneously.

Degating

Heated sharp blades with beveled edge can cut gate flush to -.010

Date Coding

Use type holders or multi-wheel numbering for permanent part I.D.

Rotary Tables & Safety Cell Machine Stands

Rotary Indexing Tables

Sonitek's Rotary Tables enhance productivity and streamline your production process. These precision-engineered tables offer smooth, efficient rotational movement for quick and easy part handling.

- Various sizes available

- Precision indexing for accurate positioning

- Durable construction for long-term reliability

- Easy integration with VERTEX series machines

Safety Cells / Machine Stands

Sonitek Machine Stands provide a stable and ergonomic foundation for your VERTEX series heat staking machines, designed for industrial environments and optimal operator comfort.

- Light curtains for safe operation

- Heavy-duty construction for stability and durability

- Casters for mobility (lockable for safety)

- Compatible with all VERTEX series models

- Fork lift tubes

- Available with storage options for tools and accessories

Options & Accessories

Calibration

Self-Calibration procedure & software for measurement values of Time, Pressure, Temperature, Distance for increased accuracy and compliance purposes. Sonitek supplies the following:

-

User-Calibration Feature & Certificate:

- Enables embedded controls on Vertex machine for calibration.

- Includes initial Factory Calibration & Calibration Certificate

-

Calibration Toolkit (P/N 600-1320 or 600-1319 for AB Controls):

- Includes 1 manual & Calibration Worksheet for step-by-step customer-calibration instructions for customer use.

- Includes 1 set of adaptor cables, fittings, & harnesses for connecting customer calibration equipment to a Vertex Machine

-

Calibration Equipment (P/N 600-1321):

- Includes recommended calibration equipment such as a thermocouple simulator, digital pressure gauge, oscilloscope, blank Calibration Certificate, and Calibration labels.

Option 1 is sold per machine.

Options 2 and 3 can be used on multiple machines.

Specifications

| Model | VERTEX MINI Press | VERTEX MAX Press |

|---|---|---|

| Weight: | Approx. 170 lbs. (77 kg) | Approx. 300 lbs. (136 kg) |

| Footprint: | 14.01" wide (356mm) x 20.51" deep (521mm) x 33" high (838 mm) | 16" wide (406 mm) x 26.625" (676 mm) deep x 40.5" high (1029 mm) |

| Throat Depth: | 5" (127 mm) | 8" (203 mm) |

| Stroke: | 5" (127 mm) | 5" (127 mm) |

| Height Adjustment: | 13.5" (342 mm) | 19" (483 mm) |

Power & Zone Options

Air Requirement

ALL MODELS: Clean (5 micron), dry air, 80 psi @ 20 CFM min.

Air Consumption Calculation

Air consumption = Stroke length (in.) x Bore Size x Cycles/min x SCFM factor

Power Factor:

- 3.14 = V3 Series

- 7.07 = V5 Series

- 12.57 = V10 Series

- 19.64 = V20 Series

* Lower forces also available via an optional "Low Force Option" package.

Downloads

- Full Dimensions: Vertex MINI Press (.PDF) & Vertex MAX Press (.PDF). Also: Comparison Dimensions (.PDF)

- Literature: Download Literature (.PDF)

- CAD Files: Vertex MINI Press CAD (.STP) and Vertex MAX Press CAD(.STP)

- Electrical Load Limits: Download Load Limits.PDF

*Specifications and design are subject to change without any notice or obligation on the part of the manufacturer.