Heat Sealing (Foil, Membrane, Film, Filter)

Heat Sealing (Foil, Membrane, Film, Filter) is backordered and will ship as soon as it is back in stock.

Contact us! Our Sales Engineers are here to guide you on plastics joining and help you select the right machine. Reach out for inventory levels, pricing, or to make a purchase.

Sonitek® Heat SealingThermal Presses

Overview

Sonitek Heat Sealing Thermal presses are state-of-the-art machines designed to deliver precise, reliable, and efficient heat sealing solutions across various industries. These presses are engineered to handle a range of materials and applications, providing robust and tamper-evident seals critical for maintaining product integrity and quality.

Technical Applications

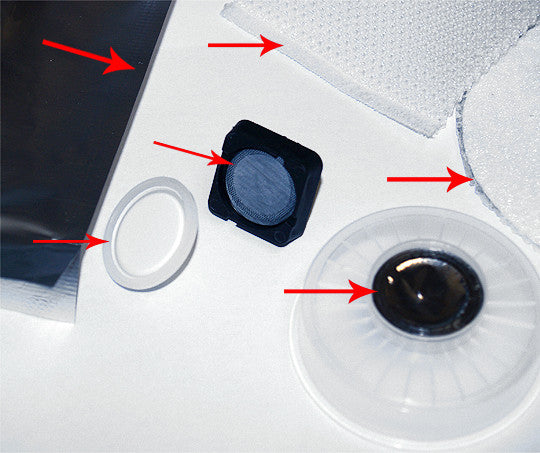

Sealing PTFE Membranes and Filter Media

PTFE membranes and other filter media require precise temperature control and pressure application to ensure an effective seal without compromising the material's filtration properties. Sonitek thermal presses offer fine-tuned temperature and pressure settings, enabling consistent and reliable sealing of these delicate materials.

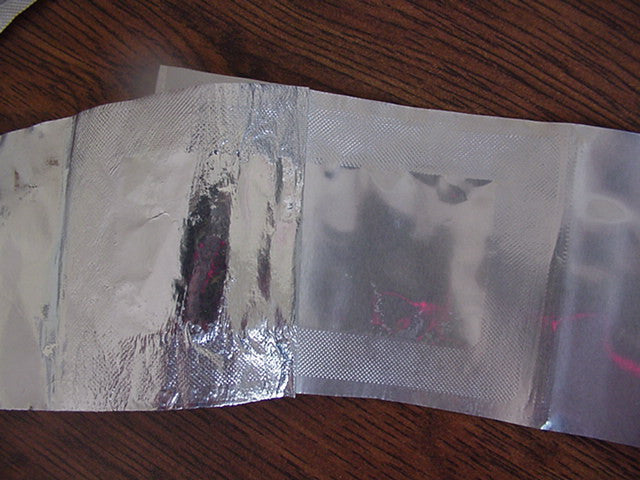

Heat Seal Films, Foils, and Tamper-Evident Packages

Heat sealing films and foils involves the application of controlled heat and pressure to create a bond that is both strong and tamper-evident. Sonitek presses are equipped with advanced thermal control systems that ensure uniform heat distribution, resulting in high-quality seals for various packaging applications, including food, pharmaceuticals, and consumer goods.

Heat Sealing Connectors to PCBs and LCDs

In electronic manufacturing, attaching connectors to PCBs and LCDs requires precision to avoid damage to sensitive components. Sonitek thermal presses utilize precise temperature and force control to achieve reliable connections, ensuring durability and performance in electronic assemblies. These presses can handle a variety of connector types and substrates, making them versatile tools in electronics manufacturing.

Key Features and Advantages

- Precision Control: Advanced thermal and pressure control systems ensure consistent and repeatable results.

- Versatility: Capable of handling a wide range of materials, including PTFE, films, foils, and various substrates used in electronics.

- Efficiency: High-speed operation reduces cycle times and increases throughput, making the process cost-effective.

- Customization: Adjustable settings allow for optimization of sealing parameters to suit specific application requirements.

- Compact Design: Space-saving footprint integrates easily into existing production lines.

- Safety: Built-in safety features protect operators and ensure compliance with industry standards.

Industries and Applications

Sonitek Heat Staking Thermal presses are utilized across various industries, including:

- Medical Devices: Sealing of sterile packaging and medical components.

- Consumer Electronics: Attaching connectors to PCBs and LCDs.

- Packaging: Creating tamper-evident seals for food, pharmaceuticals, and consumer goods.

- Filtration: Sealing filter media and PTFE membranes.