High Tonnage Series Heat Staking Machines

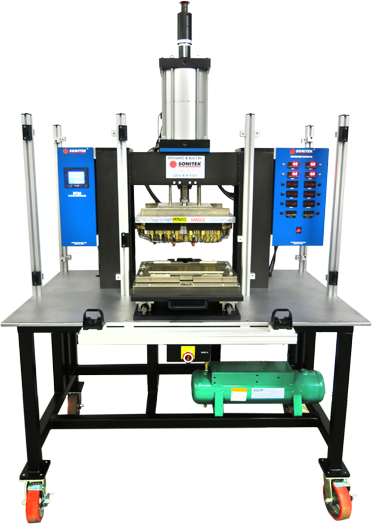

The High Tonnage thermal press is our new advanced compact bench top or table top system with easy to use COLOR touch screen controls (HMI). This more advanced model provides closed loop process controls and process parameter windows and also allows for additional options and accessories for better control and use while heatstaking.

Available in either 120V or 240V (50/60Hz) and with three different force models, the High Tonnage Series system is ideal for all thermal secondary and sealing operations requiring high tonnage forces. Press forces range from 1-1/2 to 5 tons depending on model chosen.

MODEL HT1500

1-1/2 ton bench top

MODEL HT2500

2-1/2 ton bench top

MODEL HT5000

5 ton C Frame

only available as table top

Available Configurations

Six or Twelve Zones:

Can be configured for 6 or 12 zones depending on application.

6 Zone Configuration

12 Zone Configuration

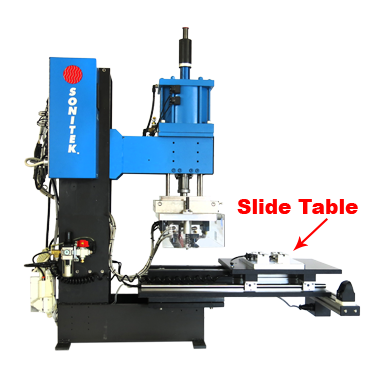

Slide Table

Load parts "Out and Away" from pressing area. Makes assembly easy!

Features & Benefits

Gross Head Adjustment

Designed with a rack and pinion beveled gear mechanism for ease of moving head up and down to next position/application

Multi-Zone Temperature Controllers

The use of the multiple temperature zones allows individual control of each staking or insertion tool (±2°F) when it's required in an application. The High Tonnage series systems can be supplied with unlimited individual temperature zones.

Digital Dwell Timer

For precise control of the staking application once contact has been made with the product. This timer provides timing from .01 seconds up to hours. Programmable time ranges include hundredth of seconds, tenths of seconds, seconds and minutes.

Slow Speed Control

Incorporated in the High Tonnage series systems is a pneumatic check unit/slow down device. This device is adjustable so it can be positioned anywhere within the stroke of the heated tools. Generally the tooling head contacts the speed control just prior to the heated tooling making contact with the plastic stud or insert to be staked. The speed control device is adjustable to control how fast or slow the stake is being performed.

Post Cooling Feature

Our unique post cooling feature is used on staking applications to insure a consistently tight assembly and prevent plastic adherence or stringing on the hot tool. The post cooling air line is located adjacent to the heated tip and is adjustable in cooling time and air flow to the tool. This feature allows us to shorten cycle times by using elevated temperatures to "remold" the plastic part through use of true melting and cooling much like a molding machine.

Spring Loaded Plunger

Mounted to tooling head to apply pressure to work piece prior to and after staking.

Multi-Point Tooling Probe

Our custom designed 340 watt thermal probes have an integral thermocouple at the heater/tip interface for optimum temperature control of the process tool. The probe has a 1/4-28 tapped face to accept interchangeable tips. The High Tonnage series systems can be supplied with multiple probes per temperature zone or an unlimited amount of probes, each individually controlled.

Optical Touch Buttons

Ergonomically designed photoelectric switches eliminate hand, wrist and arm stress associated with repeated mechanical switch operation. Because no physical pressure is applied, risk of carpel tunnel syndrome is reduced and operator productivity and comfort is increased.

Pre-Heat Option

Stops travel at the insert to allow the inserts to pre-heat, then drives them in. Eliminates hoop stress and cold press-in.

Standard Features

- ✓ Heavy duty welded steel H Frame

- ✓ Cushioned air cylinder

- ✓ 4" stroke with precision twin die set ball bushings and four hardened steel shafts

- ✓ Gross head height mechanism with rack and pinion gear mechanism

- ✓ Micrometer style positive depth stop with locking mechanism

- ✓ Air filter regulator lubricator

- ✓ Pressure gauge

- ✓ Ram speed up/down control

- ✓ Chrome plated ground steel work table with leveling capability

- ✓ Dual anti tie-down palm buttons with E-stop

- ✓ Microprocessor based integrated system controller with multilingual display menu

- ✓ Digital dwell timer

- ✓ Comprehensive instruction manual

- ✓ Operator lock-out controls

- ✓ Photo Optic Activation switches (opto-touch)

Options

Specifications

| MODEL NUMBER | HT1500 | HT2500 | HT5000 |

|---|---|---|---|

| Nominal Pressure | 1 Ton (907 kg) | 2 1/2 ton (1360kg) | 5 Ton (2268 kg) |

| Clamp Pressure @ 100psi (7 bar) | 1963 lbs. (890 kg) | 2827 lbs. (1282 kg) | 5026 lbs. (2280 kg) |

| Cylinder Bore Diameter | 5" (127mm) | 6" (152mm) | 8" (203mm) |

| Throat Depth-from center of head | 8.5" (216mm) | 9.5" (241mm) | 12.5" (318mm) |

| Head Stroke -Standard -Optional |

4" (102mm) 6" (152mm) |

4" (102mm) 6" (152mm) |

4" (102mm) 6" (152mm) |

| Ground Steel Work Table | 12"x15"x5/8" (305x381x16mm) |

12"x20"x3/4" (305x381x16mm) |

15"x20"x3/4" (381x508x19mm) |

| Dimensions -Height -Width -Depth |

41" (1040mm) 28" (711mm) 25" (635mm) |

48" (1219mm) 28" (711mm) 27" (686mm) |

49" (1245mm) 35" (888mm) 34" (863mm) |

| Air Consumption @80psi (6bar) 20 cycles per minute |

8.5 scfm 240 l/min |

13.5 scfm 375 l/min |

21 scfm 600 l/min |

| Weight -Uncrated -Crated |

350 lbs. (159 kg) 450 lbs. (203 kg) |

375 lbs. (170 kg) 475 lbs. (215 kg) |

450 lbs. (204 kg) 550 lbs. (250 kg) |

| Power Factor | 27.047 | 49.038 | Contact us |

| Electrical Service | System Controller 120 VAC Heated tooling platen 220 VAC |

Consult Factory For More Information |

Consult Factory For More Information |

| CAD Files (.STP) | HT1500 CAD File (.STP) | HT2500 CAD File (.STP) | Contact Us |

Air Consumption Calculation

Air consumption = Stroke length (in.) x Bore Size x Cycles/min x SCFM factor

Power Factor:

- • 3.14 = V3 Series

- • 7.07 = V5 Series

- • 12.57 = V10 Series

- • 19.64 = V20 Series