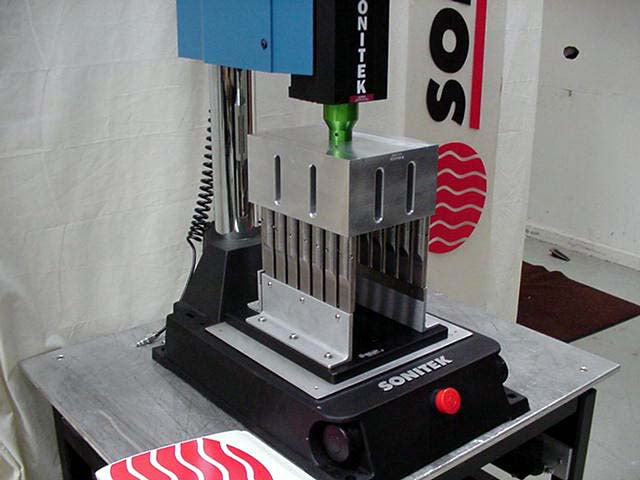

Ultrasonic Clamshell Sealing by Sonitek®

Overview

There is nothing faster than Sonitek's Clamshell & Blister Pack Sealing! Ultrasonics eliminates adhesives, glues, staples, clips, RF & thermal. No other sealing process is faster or as cost-effective as ultrasonics!

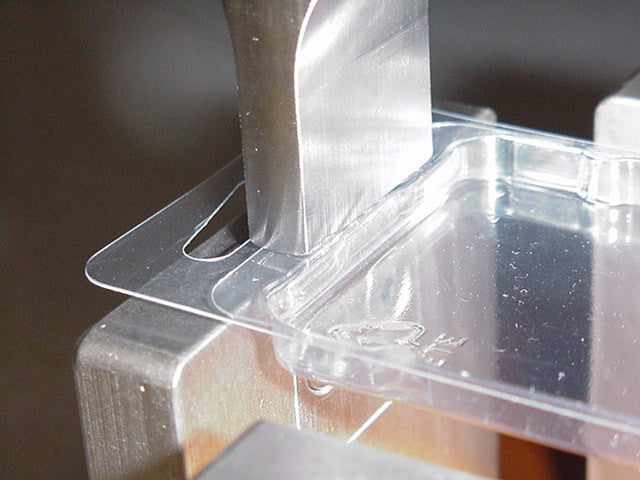

What is Ultrasonic Clamshell Sealing?

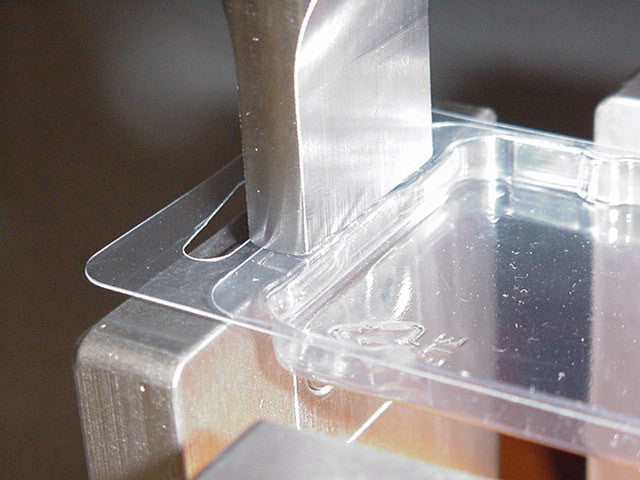

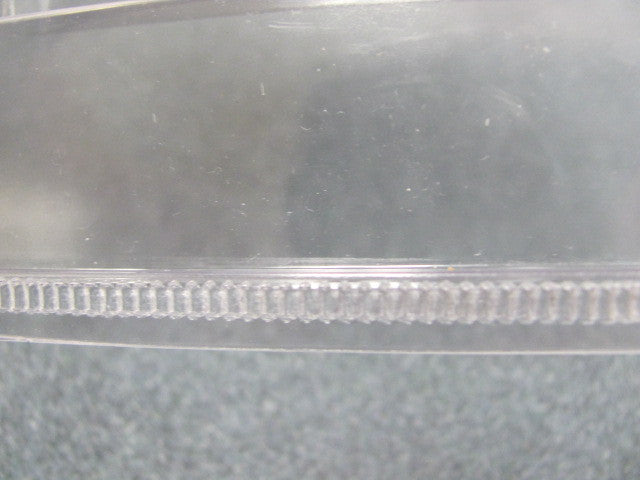

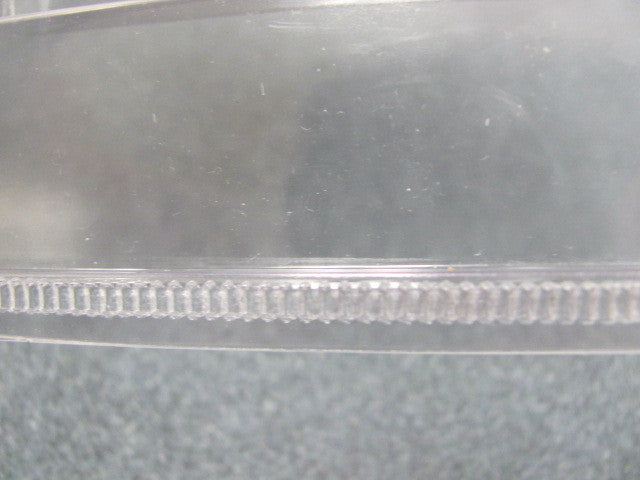

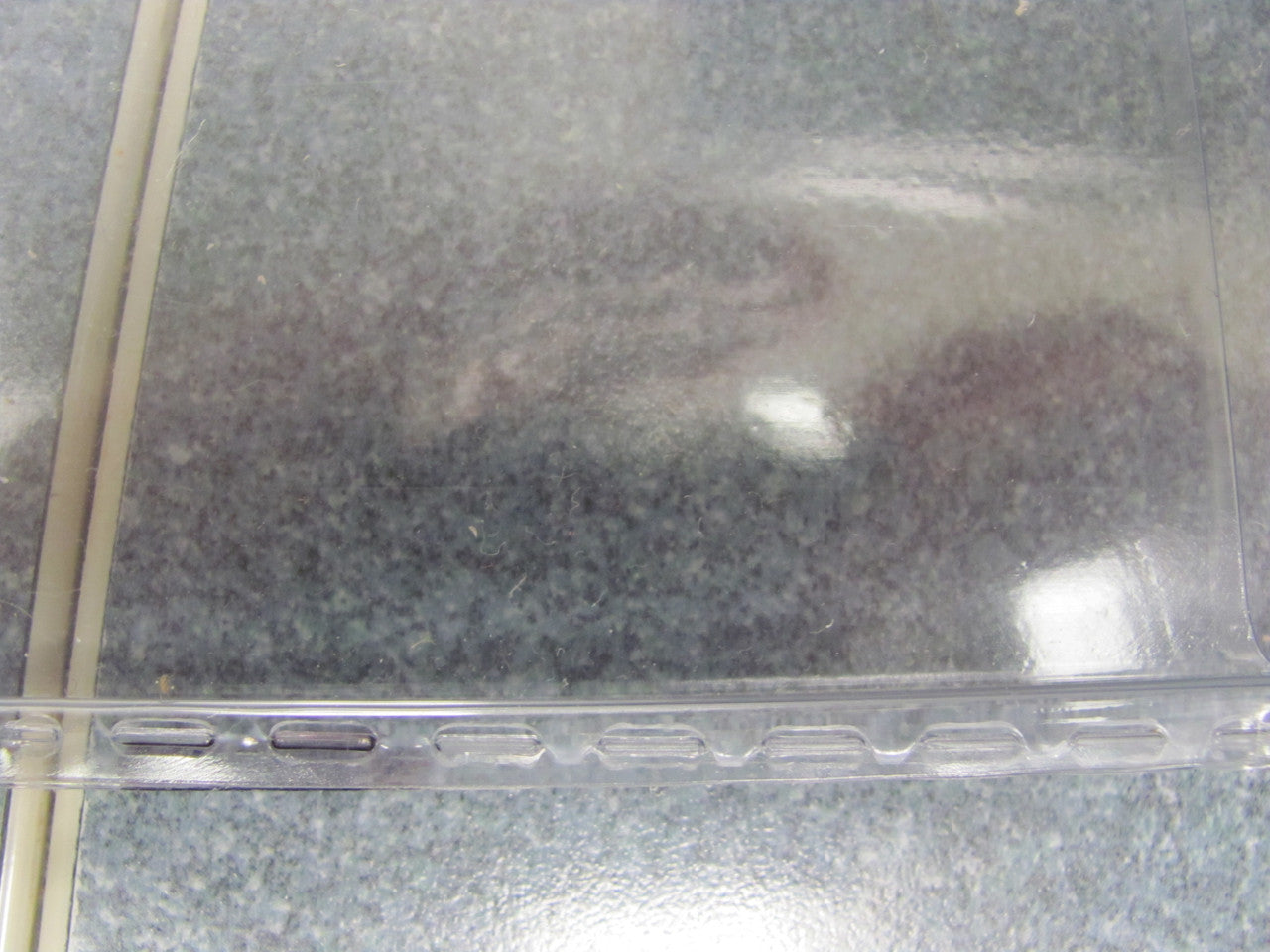

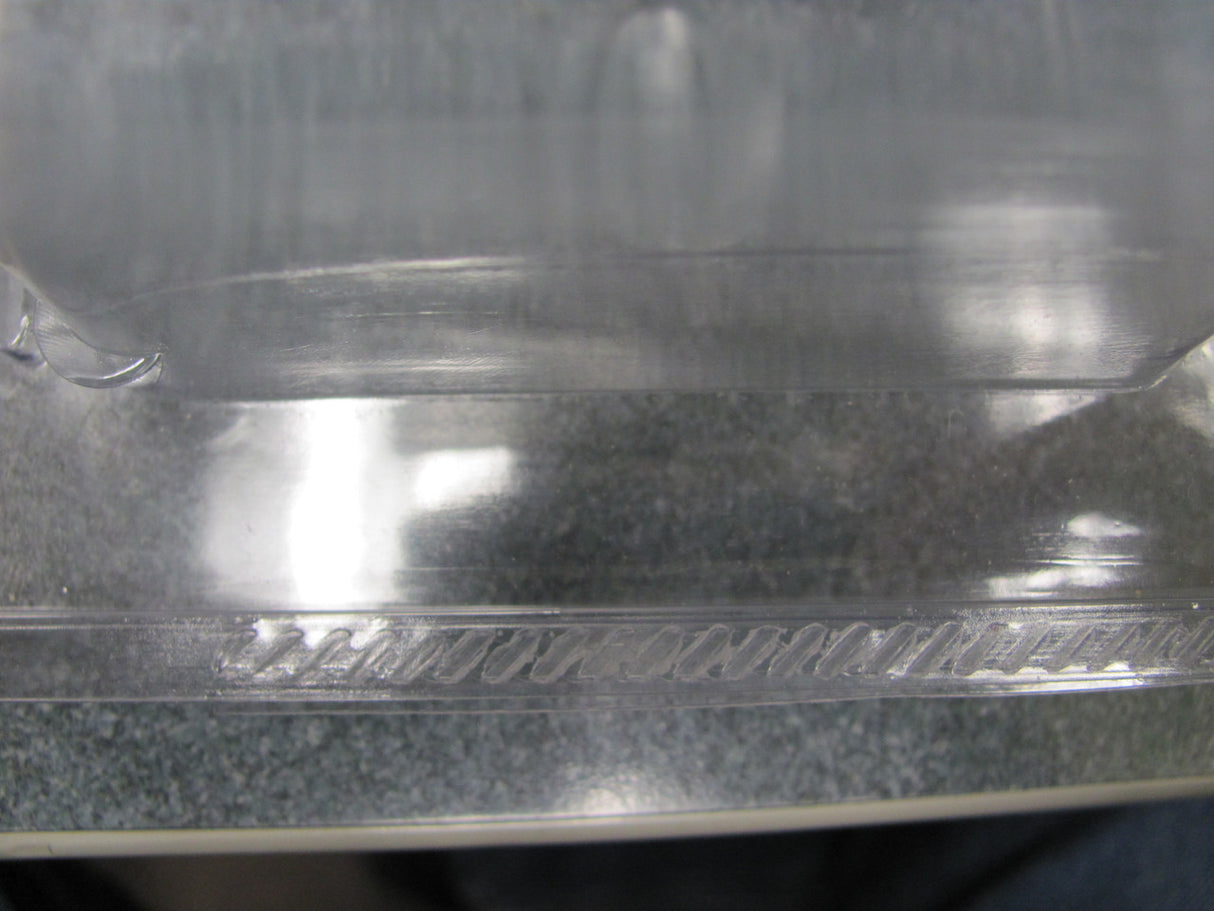

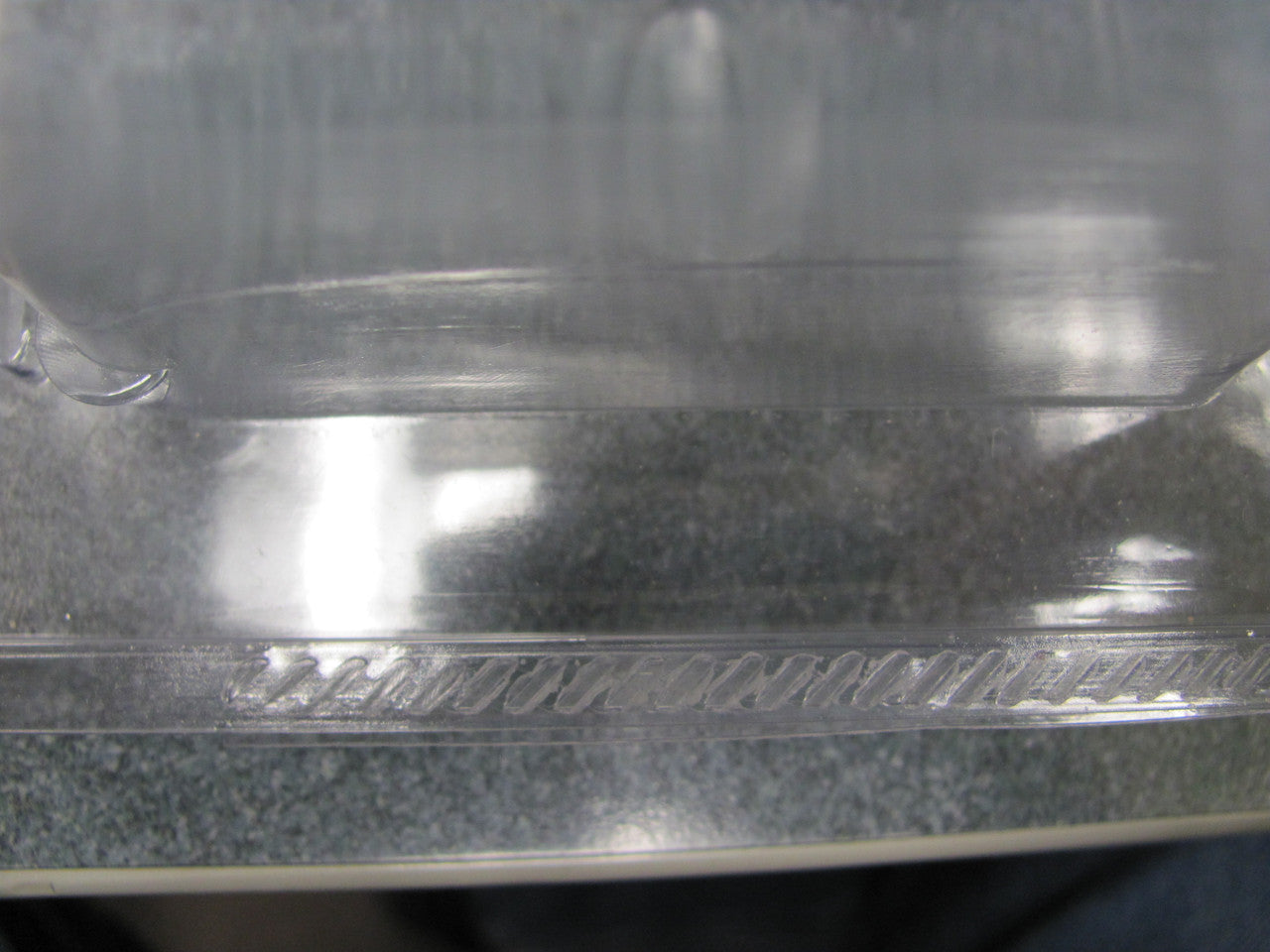

Ultrasonic clamshell sealing is a packaging method that uses high-frequency vibrations to create a strong bond between plastic materials. The vibrations cause the plastic molecules to soften and bond together when held in place by a sealing anvil, creating a tamper-proof seal. This process is highly efficient, providing a secure and durable seal that meets all major retailers' requirements for packaging integrity.

Why Choose Ultrasonics?

- Eliminates adhesives, glues, staples, clips, RF & thermal

- Provides tamper-proof protection

- Meets all major retailers' sealing requirements

- Versatile and easily configurable equipment

- Low-cost and energy-efficient

- Safe: no RF damage to electrical circuits or wiring, environmentally safe and recyclable

- High speed: up to five times faster than RF

- Space-saving: small footprint fits anywhere

- Seals various materials: PET/ETE, PETG/RPET, PVC, Styrene, Polypropylene

- Aesthetically pleasing: limitless seal patterns

Typical Uses

- Bench-top style plunge sealers

- Bench-top semi-automatic systems for end-of-line flexible conveyors

- Hand-held small spot welders for low volume small seal areas

- Rotary systems with automatic eject stations for higher volumes

- Less base models for integration into automatic packaging systems

Packing Applications Ideal for Ultrasonic Sealing

- Aseptic

- Bagging

- Carton

- Clamshell/Blister Pack

- Corrugated Plastic (mail totes, etc.)

- Cups

- Shrink Wrap Packaging

- Microwave/Oven Board

- Pouches

- Medical

- Spouts

- Strappings

- Tamper Evident/Safety Caps

- Tubes

- Zip Lock Bags