What is Ultrasonic Welding?

Ultrasonic welding is a process that joins materials—typically thermoplastics or metals—using high-frequency mechanical vibrations. These vibrations generate heat through intermolecular friction at the interface of the materials, causing them to melt and fuse together at a molecular level. Ultrasonic welding is widely used in industries requiring precise, clean, and rapid joining without additional consumables.

How Does It Work?

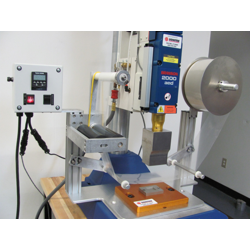

In ultrasonic welding, an ultrasonic horn (sonotrode) delivers high-frequency vibrations to the materials under pressure. The localized vibrations cause the materials to heat and soften at the interface, enabling them to bond upon cooling. Key process parameters such as amplitude, pressure, and weld time are carefully controlled to achieve optimal joint strength and consistency.

Sonitek provides comprehensive ultrasonic welding solutions:

- Ultrasonic Tooling, Horns, Fixtures/Nests: An extensive range of ultrasonic tooling designed for precision and durability, accommodating various materials and joint designs.

- Handheld Ultrasonic Welders: Portable and efficient solutions for applications requiring mobility. Ideal for spot welding, staking, inserting, and repairs outside traditional manufacturing settings.

- Custom Ultrasonic Systems: Tailored ultrasonic welding systems designed to your specific requirements, ensuring seamless integration and optimal performance in your production line.

What Is It Suitable For?

Ultrasonic welding is suitable for applications requiring:

- Fast and Clean Joining: No adhesives or solvents needed, resulting in clean joints without contaminants.

- Precise Control: Ideal for delicate or intricate components where precise energy delivery is crucial.

- Material Compatibility: Effective for joining similar or dissimilar thermoplastics and certain metals.

Applications include:

- Medical Devices: Assembling components where sterility and precision are essential.

- Automotive Components: Airbag assemblies, filters, and interior parts requiring robust, reliable joints.

- Electronics: Sealing housings, encapsulating components, and assembling connectors without damaging sensitive electronics.

Sonitek’s Ultrasonic Welding Solutions

With expertise in ultrasonic welding technology, Sonitek provides equipment and tooling designed to meet the demands of modern manufacturing. Our offerings include precision-engineered tooling, robust equipment, and customized systems with advanced features like rotary indexing tables, pick-and-place robots, and vision inspection systems.